VRF Systems V-III TROPICAL Series

Features

Common features

- Greater energy efficiency

- Energy-saving functions

- Greater comfort

- Design flexibility

- High reliability

- Easy installation

- Easy service and maintenance

Series features

Outdoor unit lineup

| Space-saving combination | Energy-efficient combination | |

|---|---|---|

| 8 HP | AJY072LNTCH | |

| 10 HP | AJY090LNTCH | |

| 12 HP | AJY108LNTCH | |

| 14 HP | AJY126LNTCH | |

| 16 HP | AJY144LNTCH | AJY144LNTCHH |

| 18 HP | AJY162LNTCH | AJY162LNTCHH |

| 20 HP | AJY180LNTCH | AJY180LNTCHH |

| 22 HP | AJY198LNTCH | |

| 24 HP | AJY216LNTCH | AJY216LNTCHH |

| 26 HP | AJY234LNTCH | AJY234LNTCHH |

| 28 HP | AJY252LNTCH | AJY252LNTCHH |

| 30 HP | AJY270LNTCH | AJY270LNTCHH |

| 32 HP | AJY288LNTCH | AJY288LNTCHH |

| 34 HP | AJY306LNTCH | AJY306LNTCHH |

| 36 HP | AJY324LNTCH | AJY324LNTCHH |

| 38 HP | AJY342LNTCH | AJY342LNTCHH |

| 40 HP | AJY360LNTCH | AJY360LNTCHH |

| 42 HP | AJY378LNTCH | AJY378LNTCHH |

| 44 HP | AJY396LNTCH | AJY396LNTCHH |

| 46 HP | AJY414LNTCH | AJY414LNTCHH |

| 48 HP | AJY432LNTCH | |

| 50 HP | AJY450LNTCH | |

| 52 HP | AJY468LNTCH | |

| 54 HP | AJY486LNTCH |

System overview

Excellent energy saving

The all-inverter heat pump provides highly energy-efficient air conditioning for individual cooling and heating operation all year round.

Great design flexibility for placement in any building

Design flexibility meets the diverse installation needs of high-rise buildings for air conditioners, such as rooftop, concentrated installation of outdoor units and installation on each floor. This can be done by large-capacity combination, sufficient connection capacity, and high static pressure design.

Easy installation and maintenance

The flexible communication method and piping connection make installation and maintenance easy even for large systems.

Features

![]() 08:38

08:38

Energy-saving technologies for boosting operational efficiency

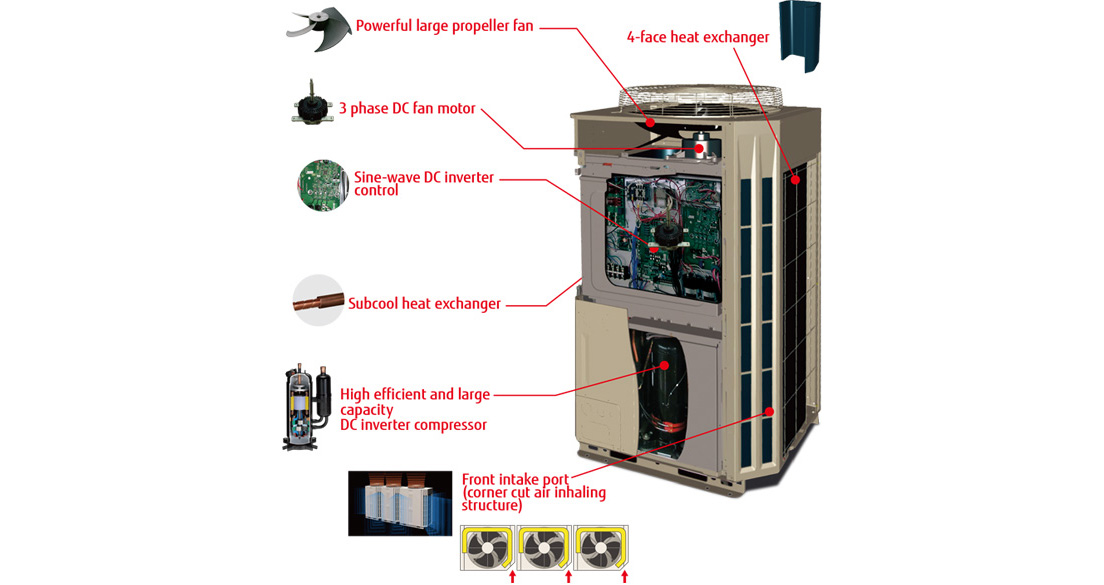

Large powerful propeller fan

The fan using CFD*1 technology achieves both high performance and low-noise operation.

- *1.

- CFD: Computational Fluid Dynamics

3-phase DC fan motor

The use of a DC fan motor with sophisticated driver control improves energy efficiency substantially. In addition, this motor operates quietly.

Subcooling heat exchanger

The double-pipe structure with internal projections achieves great heat-exchanging efficiency.

Sine-wave DC inverter control

The use of a motor with an intelligent power module (IPM) reduces switching loss and achieves great efficiency.

High-efficiency, large-capacity DC inverter compressor

A high-efficiency, large-capacity DC twin-rotary compressor offers excellent intermediate capability.

4-face heat exchanger

The 4-face heat exchanger increases the effective surface area and significantly improves heat-exchanging efficiency.

Front slanted-corner air-intake port

When multiple outdoor units are installed, the uniquely shaped front intake improves the airflow into the heat exchanger.

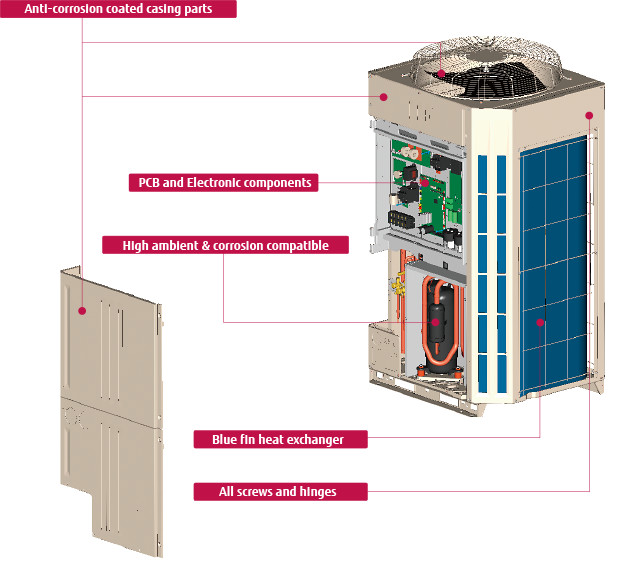

Elaborate anti-corrosion treatment

PCB and electronic components

High-ambient-temperature-compatible electronic components are used. Silicon coating is applied to all PCB circuits for corrosion protection.

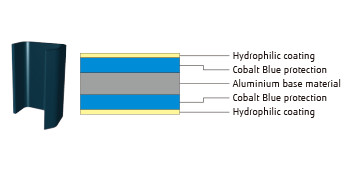

Blue fin heat exchanger

Screws and hinges

Zinc-chrome-acid film treatment applied to all screws and hinges.

Anti-corrosion coated casings

Satisfies the JRA*1 regulation for anti-corrosion treatment (JRA 4002).

- *1.

- JRA: Japan Refrigeration Association

High ambient temperature compatible and corrosion resistant

Applicable to PCB components and refrigeration cycle components

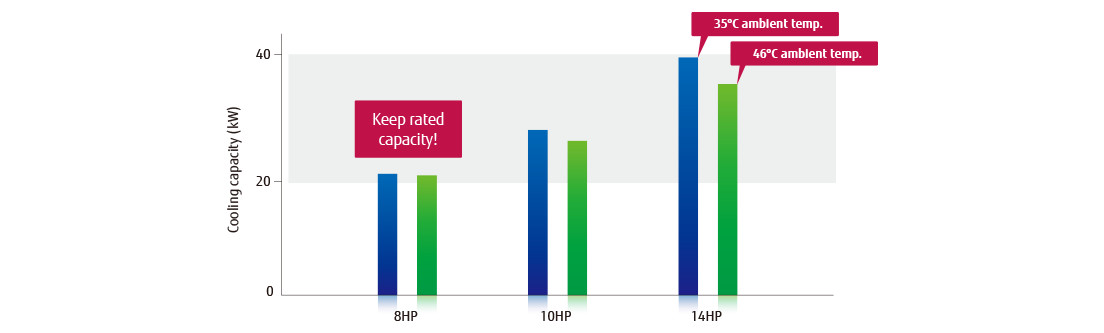

Outstanding cooling capacity

The combination of a large heat exchanger, high-capacity DC inverter compressor, and subcooling equipment provides outstanding cooling capacity.

Thailand | English

Thailand | English