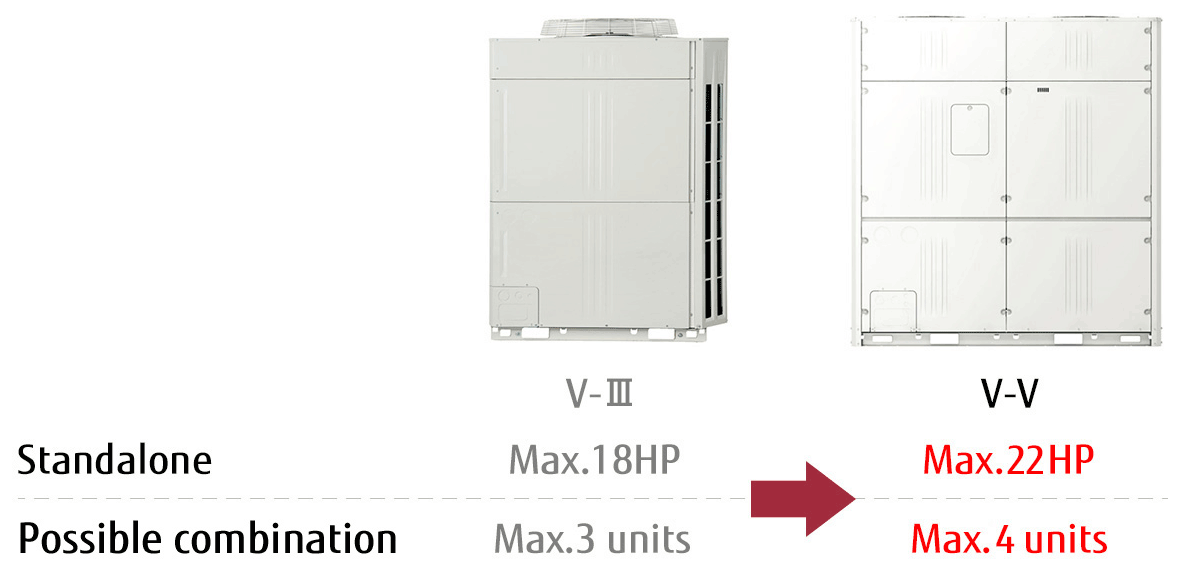

Development of a Large Capacity Model

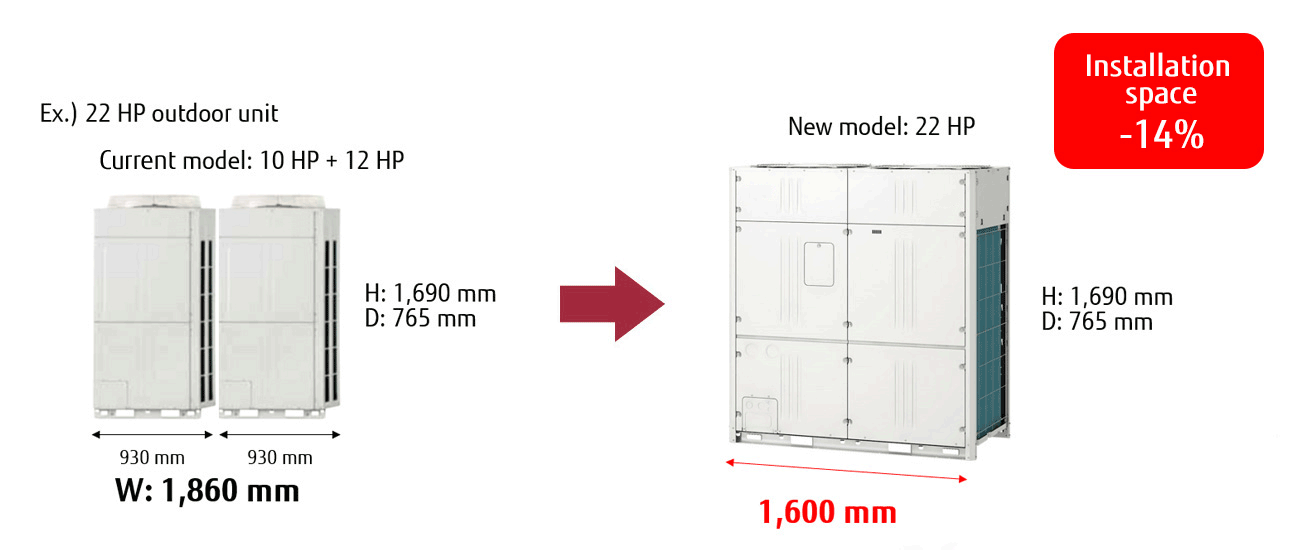

Reduced Space Requirements

The compact structure of the outdoor unit allows even greater space saving than was possible with the current model.

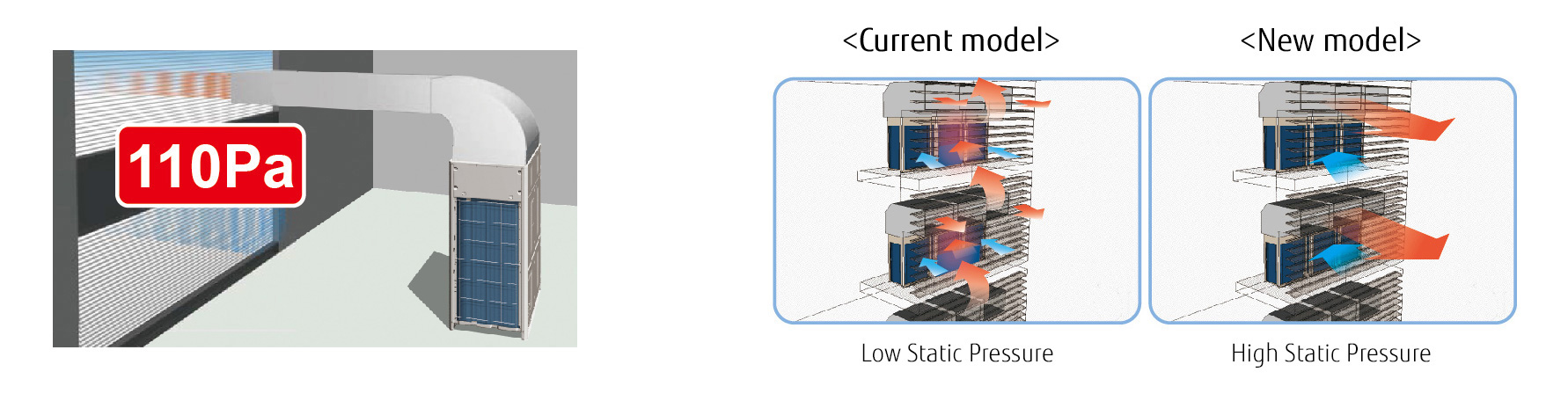

External Static Pressure Increased

The outdoor unit can have a condenser hood easily connected with a static pressure up to 110 Pa.

This allows outdoor units to be installed within plant rooms in high rise buildings.

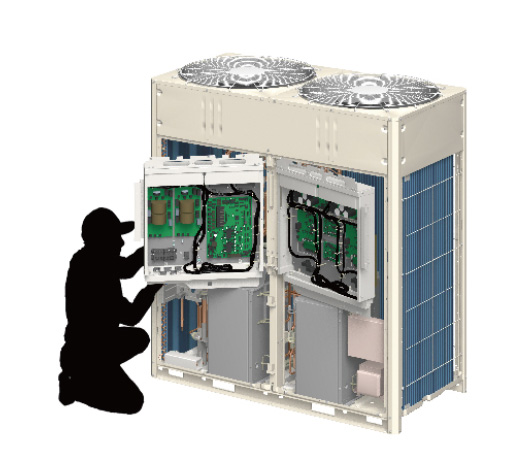

Easy Service & Maintenance

The adoption of large capacity, subdivided electrical components boxes allows work to be carried out by lone service engineers.

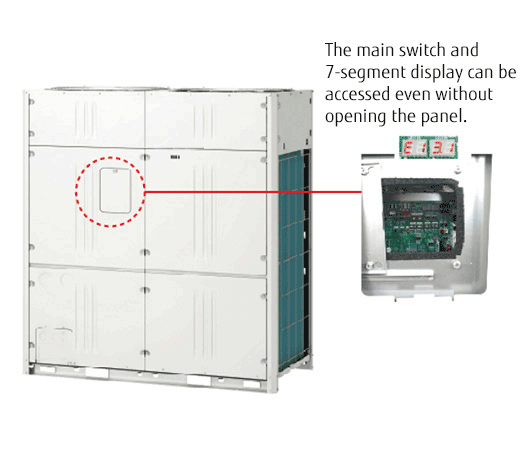

The newly created access panel allows easy access to commonly used switches during installation and maintenance.

The main switch and 7-segment display can be accessed even without opening the panel.

By subdividing the panel construction, reducing the size and weight of each panel, work can be carried out by lone service engineers.

For circuit board replacement or compressor access, only the relevant panel needs to be opened, saving time on the job.

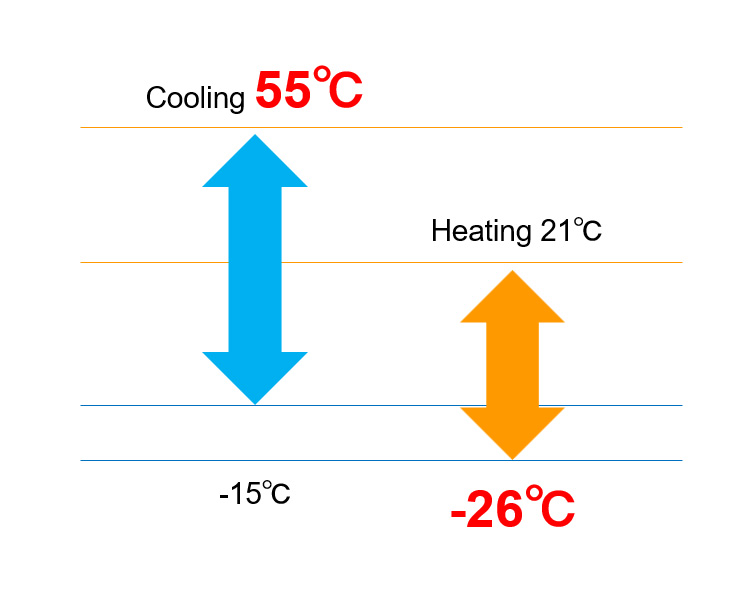

Top-class, Wide Operating Range

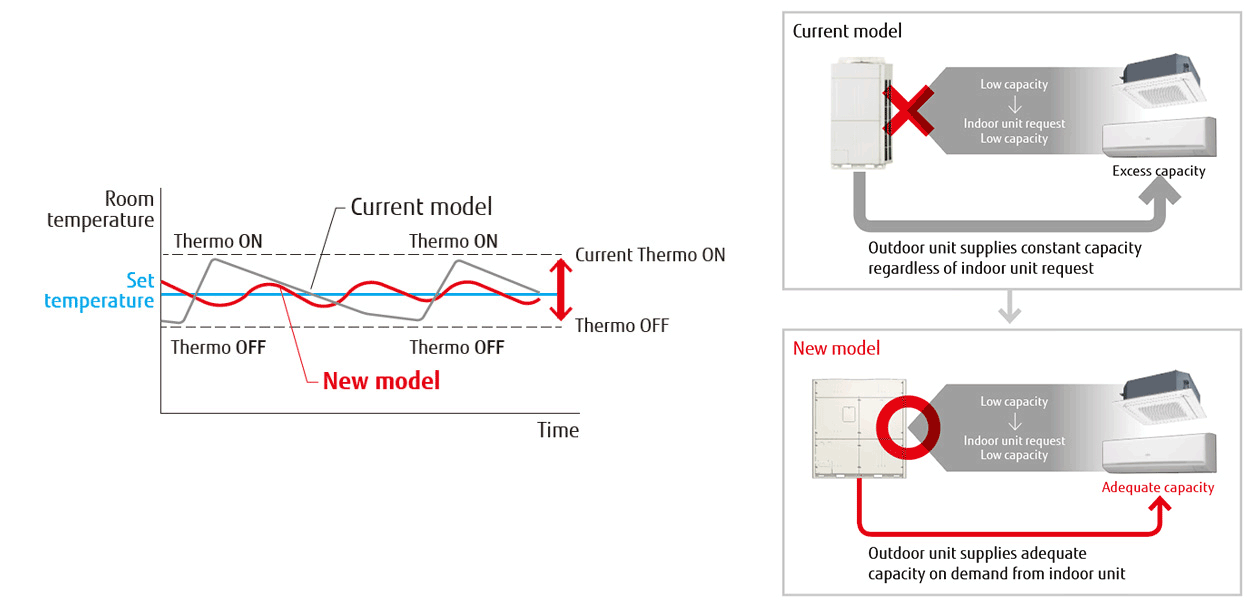

New Intelligent Refrigerant Control

The new refrigerant control operates with subtle control corresponding to heat load of the room and offers a more comfortable space. The new refrigerant control can also provide more energy savings.

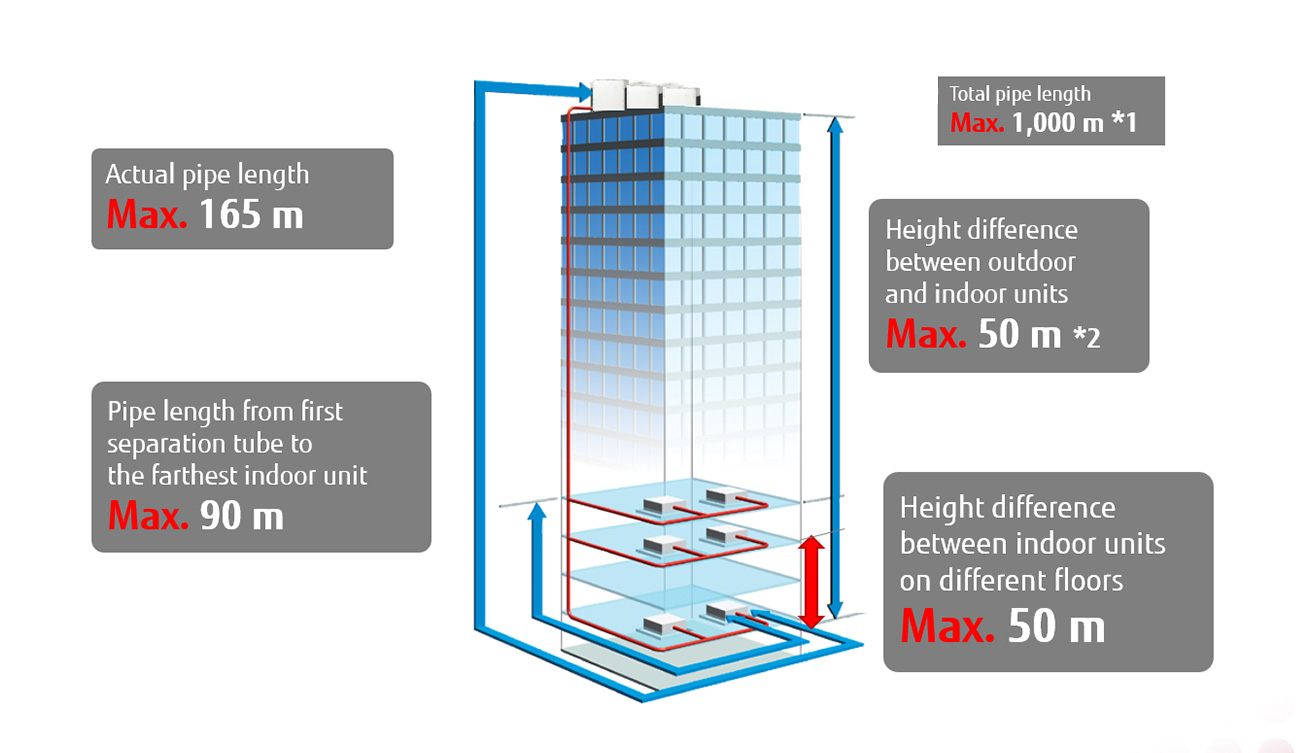

Long Pipe Design

- *1

- When using as a standalone: Max. 700 m

- *2

- When using "UTY-SPWX": Max. 110 m

GLOBAL | English

GLOBAL | English