PRESS RELEASE

January 12, 2007

Fujitsu General Limited

(NO.06-N08-26)

New release of modular type multi air conditioning system for buildings V series Suitable for large-scale office buildings, hotels and public facilities |

||

Our company will sequentially release new series multi air conditioning system for buildings "AIRSTAGE™" (V series: 6 models of 8/10/14HP outdoor units and 11 types, 50 models of indoor units) from late January.

Multi air conditioning system for buildings is suitable for large-scale office buildings, hotels and public facilities, and excels in energy-saving performance as it is capable to control the air conditioning for each individual room.

The demand for multi air conditioning system for buildings is rapidly increasing overseas as air conditioning equipment to meet the energy-saving needs with average growth of more than 10% per annum in such area as Europe, Asia and China in particular.The demand for multi air conditioning system for buildings is rapidly increasing overseas as air conditioning equipment to meet the energy-saving needs with average growth of more than 10% per annum in such area as Europe, Asia and China in particular.

Under those circumstances, our company started the sales of multi air conditioning system for buildings "AIRSTAGE™" series from 2001 and has already achieved good results in various countries such as Europe, Asia, China and Australia.

This time, aiming to further strengthen the business of multi air conditioning system for buildings, we have expanded the model line-up by developing new series (V series: 6 models of 8/10/14HP outdoor units and 11 types, 50 models of indoor units).

V series is aimed to provide large capacity with a wide range of product line-up of maximum 42HP by combining up to 3 outdoor units along with the enhancement of environmental protection measures and energy-saving performance through the adoption of R410A refrigerant and high efficiency DC inverter compressor.

Also, considerable improvement in the installation cost and efficiency as well as material saving and space saving for piping path has been realized by reducing the number of pipes connecting outdoor units with indoor units by maximum about 30%. Furthermore, flexible installation designing has been made possible to cope with the needs for large-size properties by long pipe designing allowing the installation of maximum pipe length of 150m.

In addition, the operation performance under low outdoor air temperature has been enhanced realizing the industry's top low outdoor air temperature operation (-15°C)(*1).

We will aim to further expand the business of multi air conditioning system for buildings in the world market by the development of the V series.

Modular type multi air conditioning system for buildings "AIRSTAGE™" V series

Main features of multi air conditioning system for buildings "AIRSTAGE™" V series

- Improving environmental protection measures and energy-saving performance by adopting R410A refrigerant and incorporating DC inverter compressor

- Enhancing the capacity to cope with large-scale properties by long pipe designing and increase of indoor units connection capacity

- Enhancing operating performance under low outdoor air temperature

- Improving reliability and comfort by our original control system

- "Refrigerant liquid level balance control"

- "Double tube subcool control"

- "Compressor rotation control"

- "Backup operation control"

Improving environmental protection measures and energy-saving performance by adopting R410A refrigerant and incorporating DC inverter compressor:

The energy saving performance has been improved by reducing the environmental load by adopting HFC series R410A refrigerant which has less affect to the ozone layer and at the same time realizing the high efficiency operation by equipping scroll compressor of sine-wave driving system DC inverter control.

Also, more comfortable operation has been achieved by minimizing the variation range of inside temperature against the set temperature by the inverter control.

Enhancing the capacity to cope with large-scale properties by long pipe designing and increase of indoor units connection capacity:

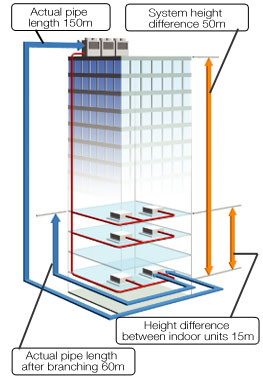

More flexible installation design has been made possible to cope with large-scale properties by long pipe designing allowing the installation up to 150m of actual pipe length, 50m of system height difference and 60m of actual pipe length after the first branching.

Also, the number of connecting indoor units per one refrigerant series has been increased to maximum 48 units and connecting capacity has been increased up to 150% of outdoor unit capacity.

Furthermore, considerable improvement in the installation cost and efficiency as well as material saving and space saving for piping path has been realized by reducing the number of pipes by maximum about 30%.

Enhancing the capacity to cope with large-scale properties by long pipe designing and increase of indoor units connection capacity:

The operation performance under low outdoor air temperature has been enhanced to make it possible to operate even in the colder region.

The industry's top low outdoor air temperature operation (-15°C)(*1) in cooling operation and up to -20°C outdoor air temperature operation in heating operation has been realized by keeping the optimum condensing pressure with our original refrigerant circuit and compressor and fan controls.

Improving reliability and comfort by our original control system

1) "Refrigerant liquid level balance control"

The "refrigerant liquid level balance control" to adjust the refrigerant volume between outdoor units in operation has been adopted by equipping with 3 sensors to detect the refrigerant volume in the receiver tank built in the outdoor unit.

Stable operation, reduction of unpleasant refrigerant noise and long piping has been realized by maintaining the appropriate refrigerant volume for each outdoor unit.

2) "Double tube subcool control"

The stable operation, along with the enhancement of cooling and heating performance, has been realized by sufficiently eliminating subcooling of refrigerant flowing into the indoor unit when cooling and controlling the condition of refrigerant flowing into the outdoor unit to the optimum when heating by adopting the subcool heat exchanger within the outdoor unit and electronic expansion valve control.

3) "Compressor rotation control"

The life of compressor was prolonged by leveling between outdoor units by rotation of the number of times the compressor is started and stopped which causes the abrasion of friction part of compressor.

4) "Backup operation control"

It has been made possible that even when one of the compressors of outdoor unit stopped condition, total system continues to operate without stopping by the emergency operation of other compressors.

Abundant line-up of 50 models indoor units including cassette, duct, ceiling, floor and wall mounted types:

Models suitable for the installation site can be freely selected from total 50 models of indoor units including cassette, duct, ceiling, floor and wall mounted types.

Cassette type

Duct type

Ceiling type

Wall mounted type

Main specifications

| Outdoor unit model | AJYA72LATF | AJYA90LATF | AJY126LATF | |

|---|---|---|---|---|

| Type | Heat pump | |||

| Refrigerant | R410A | |||

| Capacity | Cooling (kW) | 22.4 | 28.0 | 40.0 |

| Heating (kW) | 25.0 | 31.5 | 45.0 | |

| External dimensions | (mm) | (H) 1,500 × (W) 1,300 × (D) 650 | ||

| Weight | (kg) | 269 | 374 | |

Sales projection

First year 5,000 sets (outdoor units)

Note

- *1 realizing the industry's top :

- Based on our survey on January 12, 2007 at the moment.

Contact details

Contents in each releace are at the time of release.

These contents are subject to change without prior notice.

GLOBAL | English

GLOBAL | English