PRESS RELEASE

December 6,2013

Fujitsu General Limited

(NO.13-N04-24)

|

Realizing industry's top class(*1) energy saving performance New release of modular type multi air conditioning system for buildings (simultaneous cooling and heating operation type) “AIRSTAGE™” VR-II series for North America(3 outdoor unit models / 33 indoor unit models) |

||

Our company will release modular type multi air conditioning system for buildings (simultaneous cooling and heating operation type) “AIRSTAGE™” VR-II series (72,000Btu– 288,000Btu) accomplishing industry's top class(*1) energy consumption efficiency SCHE(*2) 30.1 (72,000Btu/simultaneous cooling and heating operation) for North America from December, 2013.

In the commercial use air conditioning system in North America, the central air conditioning system in which all rooms are air-conditioned uniformly is prevailing but as the enhancement of high energy-saving performance is increasingly requested, the demand for the multi air conditioning system by individual air-conditioning system which can control the room temperature for each room is growing at the pace of more than 20% every year, out of which the simultaneous cooling and heating operation type having high energy efficiency accounts for around 50%. Also, high energy saving performance and various power saving functions are requested for air conditioning appliances on the background of the strengthening of energy saving standard (ASHRAE(*3) Standard) for buildings and the acquisition of the third party certification (LEED(*4) System) rating the environmental burden of buildings.

The new series is the commercial use air conditioning system with maximum capacity of 288,000Btu combining up to 3 sets of outdoor units, and has accomplished industry's top class(*1) energy consumption efficiency SCHE(*2) 30.1 (72,000Btu/simultaneous cooling and heating operation) by our original energy saving technology such as “High density multi-path heat exchanger” and the enhancement of exhaust heat recover efficiency in the simultaneous cooling and heating operation.

Also, we developed “Touch panel type remote controller” adopting the program realizing the optimum energy saving operation conforming to the energy saving standard for buildings (ASHRAE(*3) Standard) in North America.

Furthermore, we enhanced the work flexibility by space saving of outdoor unit adopting newly developed large capacity DC twin rotary compressor and by improving facility design efficiency adopting compact “cooling and heating switching unit” and “corner-cut intake structure”.

By introducing the “AIRSTAGE” VR-II series to the market, we will aim to expand the business of commercial use air conditioners in the U.S. corresponding to the energy saving needs peculiar to North America (ASHRAE(*3) Standard and LEED(*4) System).

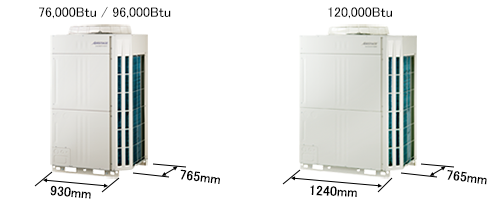

Outdoor unit of “AIRSTAGE” VR-II Series

(AOUA72 / 96 / 120TLBV)

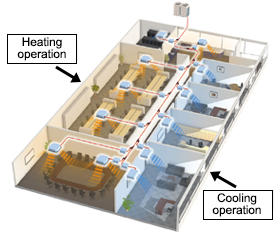

System example

Main features

- High efficiency operation accomplishing industry's top class(*1) energy consumption efficiency SCHE 30.1 (in simultaneous cooling and heating operation)

- New “touch panel type remote controller” adopting the program realizing optimum energy saving operation conforming to the North American energy saving standard for buildings (ASHRAE(*3) Standard)

- Enhancing installation efficiency and work flexibility by space saving and compact design

- Abundant product lineup corresponding to diverse buildings

1.High efficiency operation accomplishing industry's top class(*1) energy consumption efficiency SCHE 30.1 (72,000 Btu/in simultaneous cooling and heating operation)

“AIRSTAGE” VR-II series (simultaneous cooling and heating operation type) realized high energy efficiency by various original energy saving technologies and at the same time, allows for further high efficient operation by enhancing efficiency of utilizing exhaust heat during simultaneous cooling and heating operation.

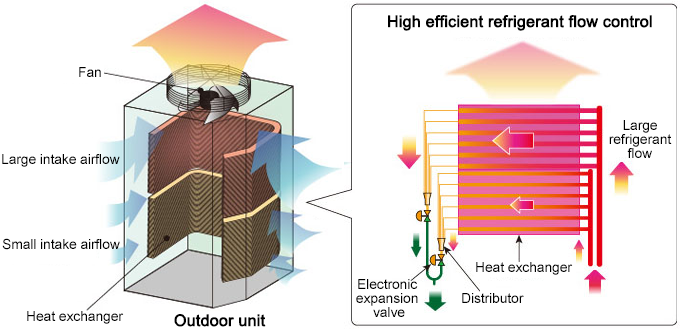

1) Realizing high efficient operation by “Round-corner type high density multi-path heat exchanger” and “Upper and lower individual refrigerant control”

In addition to the efficient “Round-corner type high density multi-path heat exchanger” (thin copper pile of Ø7mm, round-corner shape), our original operation control function is adopted to divide the heat exchanger to upper and lower parts and properly control the refrigerant volume flown into each part according to the air volume to be taken into the heat exchanger, by which the maximum performance of the heat exchanger is secured and the high efficient operation is realized.

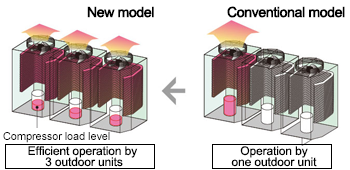

2) “Distributed operation control” fully utilizing heat exchanger of each outdoor unit

The heat exchange efficiency is substantially enhanced by making “distributed operation control” with the heat exchanger of each outdoor unit according to the operation of indoor unit.

The compressor can maintain the most efficient and stable operation without operating by the maximum load.

Also, the reliability of the equipment is enhanced as the operation is not concentrated on one outdoor unit.

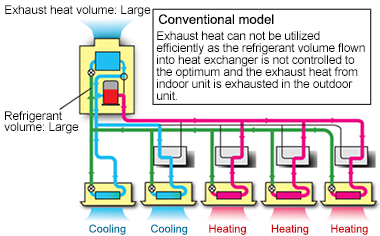

3) Refrigerant volume control utilizing efficiently exhaust heat generated during cooling operation

The high efficient operation during simultaneous cooling and heating operation was realized by the optimum control of compressor and fan motor while controlling minutely the refrigerant volume flown into heat exchanger of outdoor unit, which makes it possible to utilize exhaust heat without waste.

![Exhaust heat volume: Small, Refrigerant volume: Small. New model [VR-II] - Exhaust heat can be utilized efficiently by minimizing the refrigerant volume flown into heat exchanger of outdoor unit and exchanging the refrigerant between indoor units.](/global/news/2013/13-N04-24/images/low.png)

2.New “touch panel type remote controller” adopting the program realizing optimum energy saving operation conforming to the North American energy saving standard for buildings (ASHRAE(*3) Standard)

1) New “Touch panel type remote controller”

In North America, the standards relating to energy saving for buildings and incidental facilities are stipulated in details in the energy saving standard for buildings (ASHRAE(*3) Standard) and various power saving functions are stipulated for air conditioning system as well.

This time, the new “touch panel type remote controller” corresponding to this standard and adopting the program to realize the optimum energy saving operation was developed.

[Main functions]

- “Individual temperature setting for cooling and heating” function to prevent excessive cooling or heating by setting the set temperature of cooling operation and heating operation separately in automatic operation.

- Function of “Timer to prevent failure to turn off” to stop operation automatically after certain time and prevent useless operation in case of starting individual remote control operation during scheduled operation.

- Interlocking function with “Outdoor air intake cooling” to cool the room by outdoor air interlocking with outdoor air intake cooling (economizer) in case that cooling operation is needed even when the outside temperature is low in such place as server room or machine room.

New “Touch panel remote controller”

2) Enhancing operation easiness significantly by adopting touch panel

Pictures can be switched by one touch and required operation can be made easily.

Also, display can be made in 7 languages, not only English but also Spanish and French which are frequently used in North America and also Chinese, German, Polish and Russian.

3.Enhancing installation efficiency and work flexibility by space saving and compact design

1) Realizing space saving of outdoor unit by adopting large capacity DC twin rotary compressor

Space saving of outdoor unit was realized by adopting DC inverter control of sine wave driving system with less rotation loss and loading newly developed 16HP twin rotary compressor.

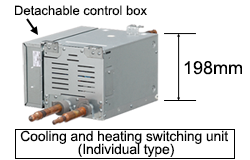

2) “Cooling and heating switching unit” to be selected according to the installation site

i. “Individual type” to be installed easily even in the narrow space

Compact design allows easy installation even in the narrow space such as under the roof. To enhance the work flexibility, the control box can be positioned either on the right or left side to suit the structure of installation site.

ii. “Collective type” to be worked simply with less pipe connection points

In the “collective type” unit combining the functions of 4 “individual type” units into one case, the pipes are connected inside beforehand and the pipe welding points at the work site are substantially reduced and the unit itself was made more compact compared with combination of 4 “individual type” units.

3) Other features (common with conventional model V-II)

- Outdoor unit with installation space saving design adopting “Corner cut air intake structure”

- Enhancing work flexibility by adopting long piping designing up to 1,000m total pipe length

- Installation in such place as each floor of high-rise building or balcony can be made because of outdoor unit of external static pressure 80P.

4.Abundant product lineup corresponding to diverse buildings

1) Corresponding to maximum 288,000Btu (84.3kW) depending on required capacity by 10 types of combination of outdoor units

| Capacity range 1,000Btu |

72 (21.1kW) |

96 (28.1kW) |

120 (35.2kW) |

144 (42.2kW) |

168 (49.2kW) |

192 (56.2kW) |

216 (63.3kW) |

240 (70.3kW) |

264 (77.4kW) |

288 (84.4kW) |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition | 72 × 1 | 96 × 1 | 120 × 1 | 72 × 2 | 72 + 96 | 72 + 120 | 96 + 120 | 120 × 2 | 72 + 96 × 2 | 96 × 3 |

2) Abundant variations by 9 types (33 models) of indoor units of 7,500 – 60,000Btu (2.2 – 17.6kW)

| Capacity range 1,000Btu |

7.5 (2.2kW) |

9.5 (2.8kW) |

12 (3.5kW) |

14 (4.1kW) |

18 (5.3kW) |

24 (7.0kW) |

30 (8.8kW) |

36 (10.6kW) |

48 (14.1kW) |

60 (17.6kW) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| Small-size ceiling cassette |

|||||||||||

| Large-size ceiling cassette |

|||||||||||

| Slim duct (with drain hose) |

|||||||||||

| Mid static pressure duct | |||||||||||

| High static pressure duct | |||||||||||

| Ceiling / Floor | |||||||||||

| Large ceiling | |||||||||||

| Small-size wall-mounted |

|||||||||||

| Large-size wall-mounted |

|||||||||||

3) Lineup of individual remote controllers corresponding to usage

Wireless remote controller

Simple wired remote controller

New touch panel type remote controller

4) Diverse central control systems to control up to 400 indoor units by one controller

Central remote controller

Touch panel controller

System controller (Software)

Main specifications / Time of release / Production quantity

| Model name | AOUA72TLBV | AOUA96TLBV | AOUA120TLBV |

|---|---|---|---|

| Power supply | 3 phase 208 / 230V 60Hz | ||

| Cooling capacity | 72,000Btu/h (21.1kW) | 96,000Btu/h (28.1kW) | 120,000Btu/h (35.2kW) |

| Heating capacity | 81,000Btu/h (23.7kW) | 108,000Btu/h (31.7kW) | 135,000Btu/h (39.6kW) |

| Dimension (H × W × D) | 1,690 × 930 × 765mm | 1,690 × 1,240 × 765mm | |

| Weight | 271kg | 290kg | |

| Time of release | December, 2013 | ||

| Production quantity | 1,000 sets (Outdoor unit base) | ||

Note

- *1 industry's top class :

- As of December 6, 2013. According to our company's survey. In the class of 72,000Btu (21.1kW) of heat-pump type in the U.S. market.

- *2 SCHE :

- Stands for Simultaneous Cooling and Heating Efficiency and is an indicator for efficiency of simultaneous cooling and heating operation stipulated by AHR (Air-conditioning, Heating, and Refrigeration Institute).

- *3 ASHRAE :

- Stands for American Society of Heating, Refrigerating and Air-Conditioning Engineers and stipulates the industrial standards and guidelines relating to air conditioning system.

- *4 LEED :

- Stands for Leadership in Energy and Environment Design and is a discretional rating system controlled by the U.S. Green Building Council. It is a system to evaluate energy saving and environmental burden ranging from the planning and designing of the whole building to the construction, operating and maintenance by the total points of “sustainability of buildings (premises) and access”, “water efficiency and saving”, “energy saving and use of recyclabe energy”, “reuse of materials and recycling rate”, “comfort of indoor environment”, “special credit of innovation and designing process”, “priority credit by area”

* “AIRSTAGE” is our company's registered trade mark.

Contact details

Contents in each releace are at the time of release.

These contents are subject to change without prior notice.

GLOBAL | English

GLOBAL | English