PRESS RELEASE

February 4,2010

Fujitsu General Limited

(NO.09-N07-32)

|

Realizing industry's top(*1) energy-saving performance Releasing large-size duct inverter air conditioners for Australia(Indoor units: ARTC72 / 90LATU Outdoor units: AOTC72 / 90LALT) |

||

Main features

1.Realizing industry's top(*1) energy-saving performance (EER 3.20 cooling / COP3.40 heating)

In the new products, the energy consumption efficiency improved by about 20% compared with conventional models(*2) by various energy-saving technologies and industry's top(*1) energy-saving performance (EER 3.20 at cooling / COP 3.40 at heating )was realized.

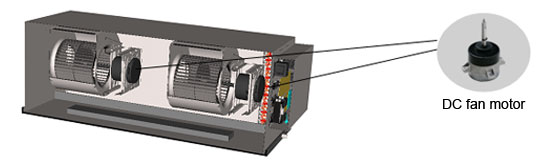

Realizing high efficiency by adopting DC fan motor for indoor unit and heat exchanger of large capacity and optimizing the housing design

Electric power consumption of motor was reduced by about 40% compared with conventional models(*2) by adopting high efficiency DC fan motor, instead of conventional AC fan motor, for indoor unit for the first time(*3) in the industry. Further high efficiency was pursued by adopting the heat exchanger of larger capacity by 25% compared with conventional models(*2) and optimizing the housing design.

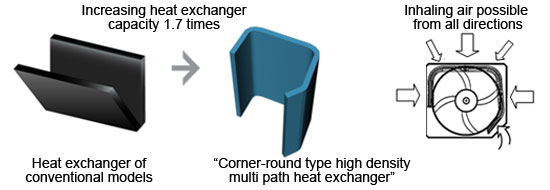

Improving heat exchange efficiency by adopting “Corner-round type high density multi path heat exchanger” for outdoor unit.

The capacity of heat exchanger was increased by about 70% compared with conventional models(*2) in spite of reducing the housing size by changing the heat exchanger of outdoor unit to corner-round shape type. Also, by the same shape, the inhaling of outside air from all directions was made possible realizing the high efficient operation.

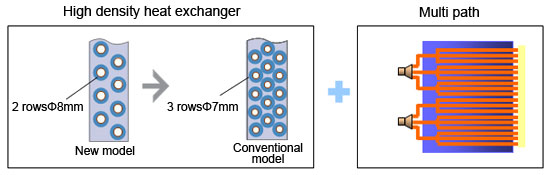

Furthermore, the heat exchange efficiency improved considerably by adopting “high density multi path heat exchanger” using thin pipes of Ø7mm.

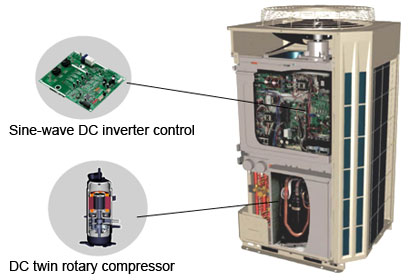

Realizing high efficiency of compressor control by adopting “Sine-wave DC inverter control” for outdoor unit

The high efficient operation of the control of DC twin rotary compressor was realized by adopting “Sine-wave DC inverter control” with less rotation loss for outdoor unit.

2. Improving installation efficiency and flexible designing

Improving efficiency of outdoor unit by realizing industry's smallest(*4) installation area

By adopting the “Corner-cut inhaling structure”, along with the adoption of “Corner-round shape heat exchanger”, the industry's smallest(*4) installation area was realized while pursuing the high efficiency. About 16% space saving compared with conventional models(*5) was realized, which improved the installation efficiency of outdoor unit.

Realizing optimum air volume corresponding to the installation conditions such as duct length

Static pressure(*6) outside the machine is controllable for the wide range of 50 – 250Pa by adopting DC fan motor for indoor unit and optimum air volume is provided to each room according to various installation conditions such as the length of duct.

Note

- *1 Realizing industry's top :

- ARTC90LATU. In 25kW inverter class in Australia (as of Feb.4, 2010)

- *2 conventional models :

- Comparison between ARTC90LATU/ AOTC90LALT and our conventional models (ART90TLC3/AOT90TPC3L)

- *3 first time :

- ARTC90LATU. Equipped with a DC fan motor in Australia 25kW inverter class. (as of Feb.4, 2010)

- *4 smallest :

- AOTC90LALT Installation area 7,115cm2. In 25kW inverter class in Australia (as of Feb.4, 2010)

- *5 conventional models :

- Comparison between AOTC90LALT and our conventional model (AOT90TPC3L)

- *6 Static pressure :

- Pressure (resistance) to block the air flow by duct connected to indoor unit

Contents in each release are at the time of release.

These contents are subject to change without prior notice.

GLOBAL | English

GLOBAL | English