AIRSTAGE MINI-SPLIT TECHNOLOGY Next Generation Refrigerants

R-32 REFRIGERANT

Fujitsu General America selects refrigerant R-32 for next generation AIRSTAGE ductless heat pump systems.

R-32 is the refrigerant chosen by Fujitsu for its next generation of AIRSTAGE ductless products, replacing R-410A. Transitioning is the right move for Fujitsu based on R-32’s performance, ease of handling, availability worldwide, and environmental benefits.

R-32 is a widely available, pure component refrigerant and is the majority component for other refrigerant mixtures like R-410A and R-454B. It has a low 100-year global warming potential (GWP) value of 675. R-32 has a safety classification of A2L, displaying mild flammability and low burning velocity. R-32 allows for more capacity by refrigerant volume, showing comparable capacities at smaller coil sizes and less refrigerant charge.

R-32 has been a commonly used refrigerant internationally since the mid-2010s. (*5) For more than a decade, Fujitsu General has been distributing R-32 products internationally, ranging from Japan to Australia/New Zealand. The North American market joins the growing list of consumers updating to R-32 ductless products worldwide.

| R-410A | R-32 | R-454B | |

|---|---|---|---|

| Composition(*1) |

50% R-32

50% R-125 |

Pure |

68.9% R-32

31.1% R-1234yf |

| GWP(*2) | 2088 | 675 | 466 |

| Refrigerant Safety Classification(*3) | A1 | A2L | A2L |

| Refrigerant Charge Compared to R-410A? | N/A | Low | Low |

| Proprietary? | No | No | Yes(*4) |

| Temperature Glide? | Yes | No | Yes |

Why is now the time for change?

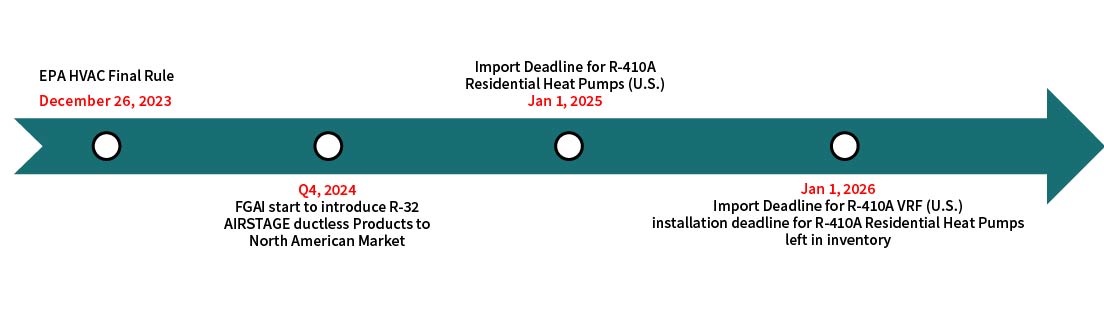

The United States Environmental Protection Agency (EPA) published a final rule(*6) in December 2023 that calls for the end of manufacturing and importing heat pumps and air-conditioners using refrigerants with a GWP higher than 700. As shown on the timeline below, residential products (and Variable Refrigerant Flow (VRF) products with a capacity <65,000 BTU/h) begin with an import deadline for R-410A products in January 2025 and follow up with an installation deadline for R-410A products in January 2026. VRF products have an import deadline set for 2026, while the installation deadline is still due from EPA.

FAQs

Can I replace the R-410A/R-22 refrigerant in my system with a new A2L refrigerant?

An A2L refrigerant is not a drop-in replacement for R-410A. Although some of the characteristics might be similar to R-410A, the use of an A2L is restricted by code and regulation to systems for which it was specifically designed.

If my R-410A outdoor unit fails, do I have to replace the whole system with a new A2L system?

You can maintain and repair your R-410A system throughout the useful life of the equipment. Faulty components/units can be replaced with a similar R-410A component. A new system installation counts as replacing more than 75% of indoor units and 100% of the outdoor units in a system.

Is it dangerous if a leak in an A2L system occurs?

The Lower Flammability Limit (LFL) for these A2L refrigerants is high. Therefore, it would take a substantial leak to achieve a combustible mixture. In addition, the minimum ignition energies for these refrigerants are very high. Cigarettes, electric heaters, candles, etc. won’t ignite them.

Also, the ASHRAE standards 15 and 15.2 specify requirements regarding refrigerant detection devices and automatic mitigation actions in case of a leak.

Will new line sets be required if I replace a whole system with a new A2L system?

ASHRAE Standard 15.2 does not require new line sets but it requires inspection and pressure testing and several other requirements if the existing line set is going to be used for a new system.

What happens if I already have a system that uses R-410A?

R-410A will still be available as a servicing refrigerant going forward, with major efforts made toward recovering and recycling existing refrigerant. The restriction on R-410A applies to newly installed systems beginning January 1, 2025, but does not restrict the use of R-410A for servicing, and even allows for replacing components of the system indefinitely. A new system installation counts as replacing more than 75% of indoor units and 100% of the outdoor units in a system.

What is a refrigerant?

A refrigerant is a volatile liquid stored air-tight in the refrigeration circuit of a heat pump or air-conditioner. This liquid is mechanically expanded into a cool gas and compressed to a hot liquid to create a refrigeration cycle, allowing the movement of heat to desired locations. Examples of refrigerants include R-410A, R-32, and R-454B.

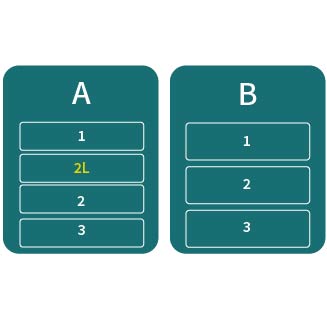

What is a refrigerant safety classification?

Refrigerant classifications are the nomenclature used by ASHRAE to identify the toxicity and flammability properties of a refrigerant. Toxicity classifications are split into “A” (nontoxic) and “B” (toxic), while flammability is split into “1” (non-flammable), “2L” (mildly flammable with low burning velocity), “2” (mildly flammable), and “3” (highly flammable). The “L,” which is only found in the A2 classification, indicates a substance that has a low burning velocity (< 4”/s). These two classifications are read together, with combinations like B1, A2L, or A3.

Why do we need to use an A2L refrigerant? Why not continue with A1s?

An A2L is a classification of refrigerant that indicates the refrigerant is non-toxic, while also having the properties of being mildly flammable with a low burning velocity. Practically, this means that while these substances are flammable, they take much more energy to propagate flames compared to their more well-known A3 counterparts (i.e., propane). With the lowered GWP levels, viable A1 options vanished (typically having high GWP values), leaving the HVAC industry to evaluate flammable refrigerants. A2Ls are a special classification of refrigerants, separated from others by their low burning velocity. In addition to being difficult to ignite, these substances also burn at a slower rate, considerably reducing the risk of any fire spreading.

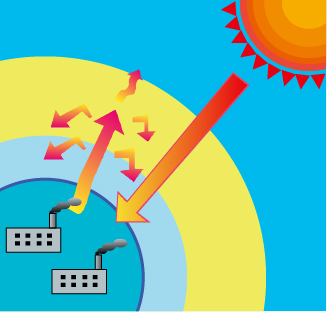

What is ‘global warming potential’?

Global warming potential (otherwise referred to as GWP100) refers to the amount of heat energy a substance is capable of absorbing over the course of a 100-year period, in comparison to carbon dioxide (CO2). For example, a substance with a GWP of 2000 would be able to store 2000 times as much energy over a 100-year period compared to an equal amount of CO2. This value is typically a way to quantify the impacts of greenhouse gases on the “greenhouse gas effect”(*7) and is an important driver of global warming legislation.

What are the advantages of single component refrigerants compared to blend refrigerants?

Compared to blend refrigerants, single component refrigerants (like R-32):

- Are simpler to manufacture and handle

- Do not have a temperature glide (explanation of glide, see below)

- Have no negative performance impact in case of a leak due to composition change

- Can be topped off in gas or liquid phases without concern about composition changes

- Can be easily reclaimed or recycled

What is temperature glide?

Temperature glide is the difference in boiling points for different components of a refrigerant mixture. The glide hampers the performance of equipment by showing less consistent temperature across the cooling coil, where each component of the refrigerant mixture boils/evaporates at its own independent boiling temperature. As a result, refrigerants with lower glide (or no glide) are more ideal for designing efficient systems. R-32 is a pure component refrigerant with no temperature glide associated, while all other next-generation options have glide.

Are there any everyday differences in installing a unit with A2L refrigerant vs. R-410A?

There are new safety and installation standards related to the use of flammable refrigerants in HVAC equipment. For more information on those requirements, please refer to the latest editions of ASHRAE 15-2022, Safety Standard for Refrigeration Systems and Designation and Safety Classification of Refrigerants, ASHRAE 15.2-2022, Safety Standard for Refrigeration Systems in Residential Applications, CSA B52:23, Mechanical Refrigeration Code, and UL Standard 60335-2-40 4th edition, Particular Requirements for Electrical Heat Pumps, Air-Conditioners and Dehumidifiers, for specifics about those requirements. Because these new refrigerants are mildly flammable, there are increased safety requirements, in some cases including measures like leak detection and mitigation strategies employed by both the equipment and the installers. There are also special handling instructions for transporting flammable fluids, which must be considered for contractors/installers using A2L refrigerants.

Who authorizes refrigerant regulations in the U.S. and in Canada?

In the U.S., HFC regulations are established by the EPA. The EPA has authority to create national regulations related to three HFC-related paths (production/consumption allowances, handling certifications, and sector limits) via the AIM Act.

In Canada, Environment and Climate Change Canada (ECCC) sets climate-related regulations and can regulate using GWP limits, which it has done in other sectors. (*8)

Canada is expected to review its national refrigerant regulations in 2024 for HVAC/R, but no proposals have been made at this time.

How will the current HFC Phasedown affect this transition?

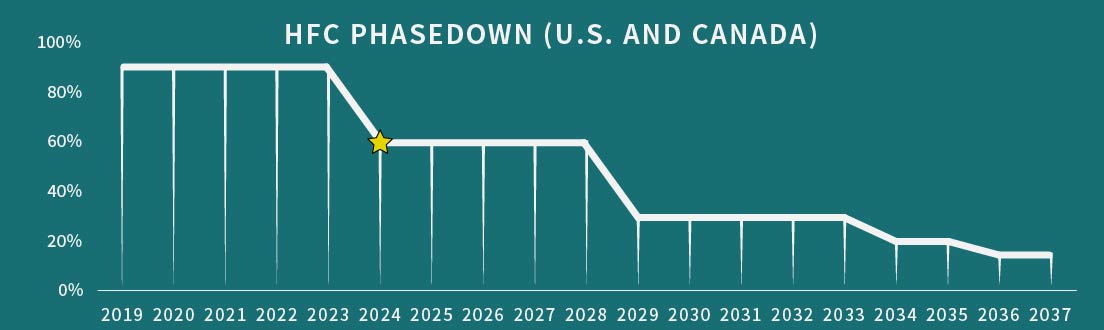

Outside of the HVAC sector GWP limits, there are broader regulations aimed at curbing both the U.S. and Canada’s HFC usage over the next decade. The current HFC phasedown schedule (for the production and consumption of HFCs), shown on page 4, is on schedule for both the U.S. and Canada.

In 2017, Canada ratified the Kigali Amendment(*9), a United Nations (UN) amendment to the Montreal Protocol which calls for developed nations (different goals set based on the level of development) around the world to phase down the use of HFC refrigerants by 85% by 2036, using the phasedown schedule shown.

Before U.S. adoption of the Kigali Amendment in 2022(*10), this phasedown schedule was followed by the U.S. EPA under the AIM Act(*11), starting its phasedown in 2022 instead of 2019. This schedule is based on a baseline for HFC usage for each country between 2011-2013, with 100% being the average HFC production/consumption across those years.

This phasedown will apply to all workable next-generation options, with less supply of new refrigerants allowed in each country as time goes on. With this phasedown looming, R-32 makes the most sense for Fujitsu because of its proven performance, availability, design advantages, and ease of reuse/recycling.

Cited Sources:

- Compositions of Refrigerant Blends | US EPA

- Fourth Assessment Report — IPCC

- ASHRAE - iWrapper

- Opteon™ XL41 (R-454B) | Chemours

- https://www.coolingpost.com/world-news/now-fujitsuannounces-r32-units/

- Federal Register :: Phasedown of Hydrofluorocarbons: Technology Transitions Program Residential and Light Commercial Air Conditioning and Heat Pump Subsector

- What is the greenhouse effect? – Climate Change: Vital Signs of the Planet (nasa.gov)

- Guide to refrigerant regulation and policy - HPAC Magazine

- Link to Canada Ratification of Kigali Amendment

- U.S. Ratification of the Kigali Amendment - United States Department of State

- Protecting Our Climate by Reducing Use of HFCs | US EPA